4 Different Types of Active Fall Protection for the Construction Industry

Updated August 8, 2019

All fall protection can be broken down into two main categories; active and passive. Of the two, passive controls are far safer, as it doesn’t require any interaction from the worker to be safe. In construction, however, it is rare to see opportunities where passive controls will be cost-effective or possible with building conditions.

With the need to use active fall protection, understanding the different types and applicable codes can create a safer work environment. It can also alleviate possible lawsuits or liability in the case of an accident.

In the construction industry, it's the employer's duty to prevent falls. The best way to do this is by maintaining a safe work environment through proper fall protection education, ensuring the use of appropriate personal protection equipment (PPE), and thorough training. It’s important to teach all workers that just because a task will only take a couple of minutes doesn’t mean you don’t need to wear PPE.

Categories of Fall Protection

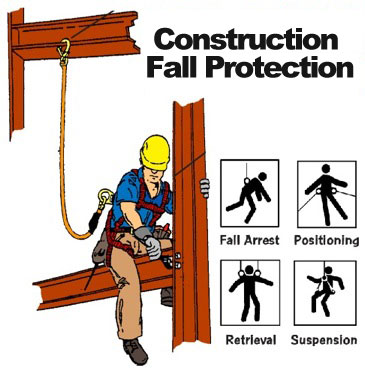

All active fall protection for the construction industry falls into four basic categories: fall arrest, positioning, suspension, and retrieval. OSHA provides standards for each category of fall protection. Here are some basic explanations and links to each set of standards.

Functional Systems of Fall Protection

- Fall Arrest OSHA 1926.502(d) - Fall arrest systems are required whenever a worker is exposed to a fall hazard. In the construction industry, OSHA defines a fall hazard as a drop of 6 feet or more from a working/walking surface to a lower level or grade. Some exceptions exist, including (but not limited to) ladders, scaffolding, and steelwork. Common fall arrest equipment includes an anchor point, body harness, and connector (such as a lanyard or self-retracting lifeline.

- A full-body safety harness is your first line of defense. However, the kind of harness you need will depend on the type of work being done. It must be capable of supporting a person with a combined tool and body weight of 310 lbs, and must be used in conjunction with an anchorage device and deceleration device that limits the impact forces of a fall to 1,800 lbs. or less. For additional help selecting the right harness, check out our buyers' guide.

- Lanyards are the one device that connects your harness to the anchor safely. These can range from a 50' SRL to a 2’ webbed lanyard. There are several different types of lanyards, all with specific purposes. Check out our additional resources on fall protection lanyards if you have any questions.

- Anchor points are the final piece of the equation. Anchor points must be able to withstand 5000 lbs or twice the anticipated load of a person free falling a distance of 6’. It is crucial that all anchor points are engineered and installed by what OSHA defines as a qualified person. The harness and lanyard can only catch you if that they are attached to doesn’t break.

- Positioning OSHA 1926.502(e) - Positioning systems allow the worker to sit back in their harness while performing work with both hands. The most common application is anytime you need to do work from a ladder. This type of protection is not designed to be used to arrest a fall and must be used in conjunction with a fall arrest system, such as body belts, harnesses, and components

- Retrieval OSHA 1926.502(d)(20) - Otherwise known as a rescue plan, retrieval is a crucial step in the development of a fall protection plan. This system covers the post-fall scenario of retrieving a worker who has fallen. OSHA does not give any instructions regarding how to accomplish this but does say that there must be a plan in place.

- Suspension OSHA 1926.452(o) - Suspension equipment systems are able to lower and support the worker providing for a hands-free work environment. This system is widely utilized by window washers and painters; a fall arrest system must be used alongside the suspension system.

If the fall risk is outside the range covered in the above categories there are other types of equipment that may be used to protect workers from falls. Technology is constantly allowing for better and safer methods to perform the same work. Let’s discuss the many options we have to help you work safely.

Need Help?

Still have questions on what is the right fall protection solution for you? Our team is ready to help.