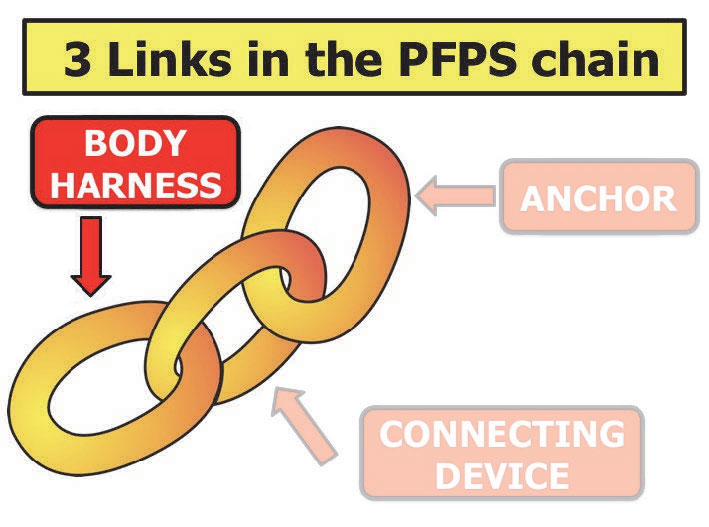

3 Components of a Personal Fall Arrest System - Part 2: Body Harness

Safety Harnesses are meant to protect your life. But a safety harness that has been worn improperly can put you at risk in multiple ways. This article will equip you with some basic information so that you can ensure you are using your safety equipment effectively.

This is the second article in our Personal Fall Protection System series. The first article covers important details about fall protection anchors.

Second Component of a Fall Arrest System: Body Harnesses

In fall arrest, it's illegal to wear a safety belt rather than a full body harness while working in a fall arrest mode.

In fall arrest, it's illegal to wear a safety belt rather than a full body harness while working in a fall arrest mode.

Although it's permissible to wear a safety belt in either positioning or fall restraint, it's still recommended that the employee wear a full body harness in every application.

The harness is superior to a belt because it:

- distributes the forces throughout the body; and

- suspends the worker upright after the fall

Find our more about how a safety harness works: How Does a Safety Harness Work?

Inspection is Key

A critical element in any program is equipment inspection. Harnesses can be broken down into 4 key components:

| HARDWARE | Any metal including D rings, buckles, snap hooks, carabiners, etc |

| FABRIC | Any straps, packs, pouches and include wire cable (even though it's not fabric) |

| STITCHING | Any tack point where two pieces of fabric are attached or sewn |

| TAGS OR LABELS | Any written information on the product |

Harnesses must be inspected by the authorized person (end user) before each use. ANSI requires a competent person inspection not less than either annually (Z359 Industrial) or semi-annually (A1032 Construction) by a competent person.

When Does a Harness Need to be Removed from Service?

Equipment is removed from service when:

- it's involved in a fall

- it fails the end user inspection

- it fails the competent person inspection

- the service life is exceeded

Maximum Harness Working Weights

The maximum working weight in a full body harness is 310 lbs. If the weight exceeds 310 lbs, there are three options available:

- select a harness with a higher working weight (i.e. 400 lbs)

- custom made harnesses are available

(with either of these options, ensure that the connecting device is also rated for a higher working weight) - stay on the ground

For further discussion on harness weight, see this article: How Much Weight Can My Safety Harness Support?

Fit Testing

As important as knowing how to don and inspect the harness, fit testing can make the difference between life and death. Practical fit tests should be conducted on a routine basis (e.g. seasonally when clothing changes).

Its become apparent that MOST end users do not know how to fit their harnesses properly. Without the fit test, you have no idea how the harness will respond should a fall occur.

Correct D-Ring Usage

D-rings are used to ensure that your body stays upright in the event of a fall. Only a dorsal or chest d-ring should be used to tie off to an anchor point. Side D-rings should only be used for positioning.

The application or use of the harness is determined by the location and number of D Rings on the harness. For example:

- Fall Arrest: Dorsal D Ring (between the shoulder blades)

- Fall Restraint: Dorsal D Ring

- Positioning: Chest, waist or hips

- Fixed (permanent) Ladders: Chest or waist

- Fall Arrest Rescue: Chest or waist

- Confined Space Rescue: Dorsal or shoulder D Rings

Discuss these aspects of a safety harness with your employees in a safety huddle or tool-box talk to ensure that you and your employees are using your equipment safely.

As someone once said, "When you gamble with safety, you bet your life." So take the necessary precautions to ensure that your are using your equipment properly