How Does a Self-Retracting Lifeline Work?

Back when I began in the field of safety, self-retracting lifelines (SRLs) were frowned upon by workers, not because the function wasn’t preferable, but because they were big, bulky, and very heavy. Over time, things have changed. Technology has improved. And while the cumbersome clunkers still exist and have their purpose, many SRL’s have become much more portable, weighing as little as just a couple of pounds.

While early nicknames for the device, like “yo-yo” are misleading in how they function, an SRL works in much the same way a car’s seatbelt does. When a certain level of speed or force is achieved, a locking mechanism engages, arresting – in the case of the seatbelt - the forward motion of a car passenger or – in the case of the SRL - the downward motion of somebody falling. To see how this works is simple. Take your SRL and hold it in your hands. Slowly pull the cable or webbing out. If you do this slowly enough, it continues to play out until it reaches its full length. Now, let it retract. This time, snap the cable or webbing out. If you pull hard enough you will see it lock into place. Congratulations, you’ve just demonstrated how SRLs work without having to toss somebody over the side of a building!

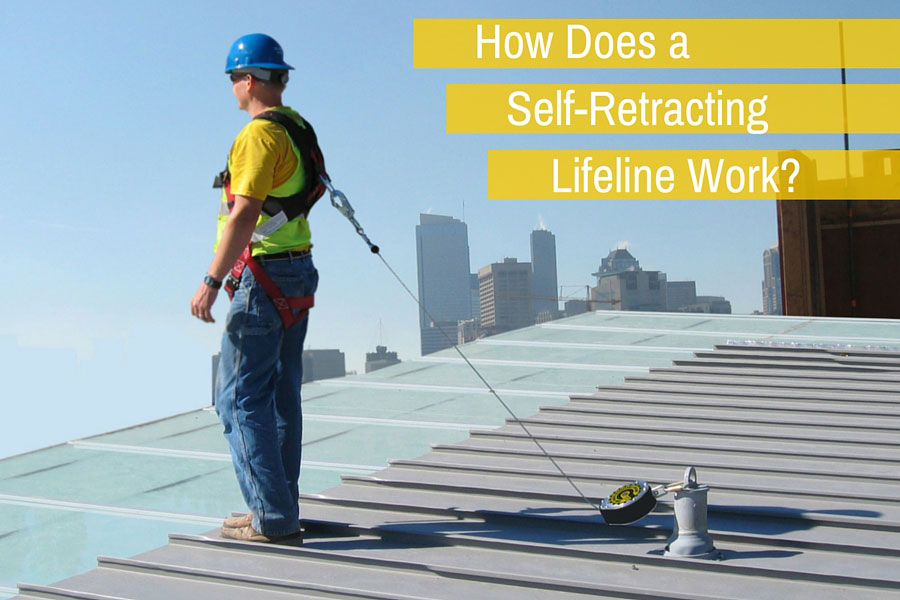

The SRL is made up of a number of parts. The housing or casing is the part you see, for the most part. It is the plastic or metal enclosure that contains most of the parts including the locking mechanism; the drum, which is what the lifeline itself winds on to; the shaft, usually a steel rod in the center around which the drum rotates; the locking mechanism itself; the motor spring which is what keeps tension on the lifeline when played out; and the lifeline itself (with snaphook for attachment).

Used properly, an SRL should stop a fall in less than 24” if you’re using a Class A SRL. “Properly” is important, though. For instance, like most fall protection, the SRL should be anchored at the height of your harness’ D-ring or above. While some may hear “retractable” and think that the cable will pull you back if you begin to fall, this is not true. What is already played out will remain played out, so if you anchor the SRL at your feet, you are adding fall distance that can place too much force on your body. The very idea of the short arrest distance of an SRL is to keep those forces at very low, very safe levels. Using an SRL on a sloped roof could also be a problem as a fall that involves the worker slipping down the slope may not reach a high enough speed to engage the mechanism. Ensure that your SRLs are always properly installed and being used in accordance with the manufacturer’s instructions.

Maintenance is key. Allowing grease, dirt, paint, or any other material to build upon the lifeline or inside the casing could cause it to not work properly. Clean according to manufacturer’s instructions. Using the wrong type of cleaning agent could be as deadly as not maintaining the equipment. Ensure that it is stored in a cool, dry place to prevent rust, rot, and other types of material breakdown. Inspect the SRL before each use. If an SRL is deployed in a fall, immediately remove it and all components of the personal fall arrest system from service. Before putting the SRL back into service, it would need to be recertified. Most of the time, in order for this to occur, the SRL would need to be returned to the manufacturer. However, some products exist now that allow for easy on-site recertification by a qualified, authorized person.

Research your options before purchasing fall protection. I find the SRL to be the preferable solution in situations where fall arrest is necessary because fall prevention through railings or other barriers cannot be achieved. Understanding how they work and what they do will help you to make the best decision for the safety of your employees.