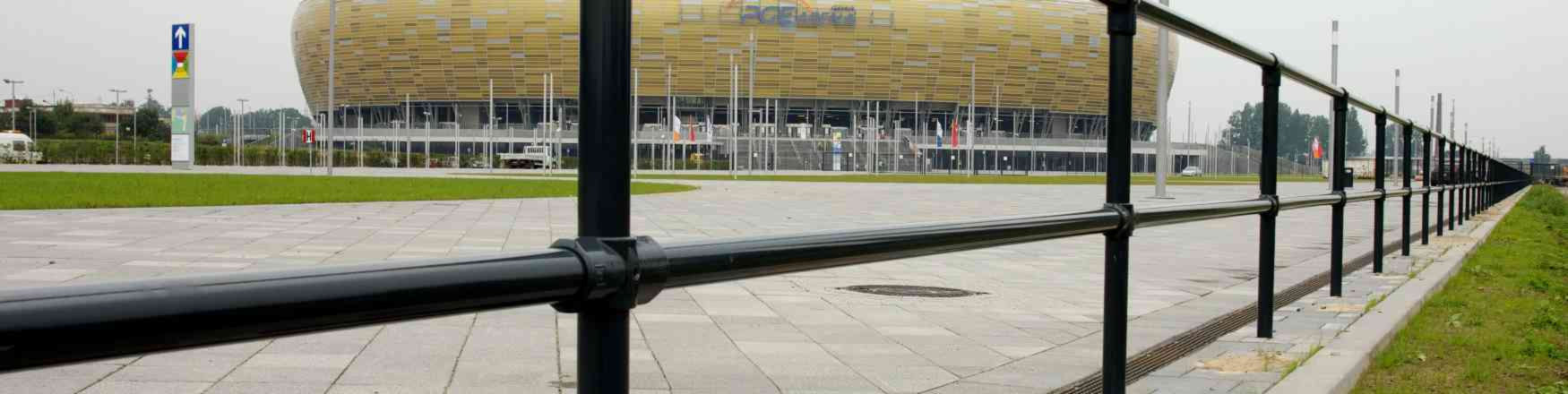

Ground Mounted Safety Railing

OSHA Compliant

Our safety team will make sure your mounted railing meets OSHA codes and your relevant local codes.

Custom Designed

Due to its modular design, our railing can be configured to the exact specifications of your site.

Strong Components

Our guardrail is galvanized inside-and-out with a proprietary coating to ensure corrosion resistant, even in the harshest environments.

Install Quickly

Whether you are self-installing or employing your favorite contractor, our railing requires no specialized tools or labor.

Advantages of Our

Gound Mounted Safety Railing

Durable, Galvanized Railing that Lasts Decades

Corroded railing is unsafe. Our components are designed for longevity and strength.

- Our steel fittings are hot-dipped galvanized to ensure each connection point remains solid.

- Our structural tube has a proprietary coating that has been shown to last up to 4x's longer than standard schedule 40 galvanized pipe.

- Our Kee Klamp fittings are the original and world standard in modular pipe fittings. Our fittings go through rigorous quality control processes that include inspections at multiple points in the manufacturing process.

Railing Designed to Fit Your Site

The guardrail's modular design makes it easy to configure and install your exact specifications. Whether you need guardrail for pedestrian walkways or warehouse railing, we will work with you to select the right material, finish, post-spacing, and layout to be OSHA compliant.

Our railing is available in a variety of finishes. Standard railing comes in galvanized steel or aluminum finishes. We also offer additional colors in additional powder-coat finishes.

Plus, our guardrail can accommodate toeboards, in-fill panels, or safety gates - to meet all your safety needs.

Easy to Install, Modify, and Repair

Installation requires no special tools or labor. The pipe components are secured with a hex set-screw to achieve a strong connection. The pipe can be cut to length for you, or shipped in full lengths for precise fitting on site.

With the modular design, our railing is just as easy to modify as it is to install. The components can be repurposed in other areas if the plan is changed onsite.

Our railing is easy to repair, unlike traditional welded railing which needs to be completely replaced when damaged. Simply disassemble any bent section of railing, replace the damaged components, and reassemble. Typical repairs take minutes, not days.

Examples of Ground Mounted Railing Systems

Commercial

Residential Railing

Municipal

Mezzanine

Machine Guarding

Pedestrian Walkways

Stairs

Infill Panels

Hazardous Areas

Ramps

Offset

Looking for Mounted Railing Kits

Kwik Kit safety railing kits allow you to easily create a durable railing system to eliminate crash hazards, keeping your facility safe. Our weldless safety railing is ideal for creating a safe and compliant workspace.

- Pre-assembled Uprights Make Installation Simple. No Complex Tools Required

- Available in aluminum or steel - Customize for Your Needs

- Pre-Coated in Safety Yellow for Clear Visibility

OSHA Codes & Guardrail Requirements

The section of the OSHA code that specifies most of the primary guardrail and handrails as it directly relates to safety railing is 1910.26. Specifically, the following sections are the most relevant to handrail and stair rail requirements.

1910.29(f)(1)(i) - Handrails are not less than 30 inches (76 cm) and not more than 38 inches (97 cm), as measured from the leading edge of the stair tread to the top surface of the handrail (see Figure D-12 of this section).

1910.29(f)(2) - The minimum clearance between handrails and any other object is 2.25 inches (5.7 cm).

1910.29(f)(4) - No opening in a stair rail system exceeds 19 inches (48 cm) at its least dimension.

1910.29(f)(5) - Handrails have the shape and dimension necessary so that employees can grasp the handrail firmly.

1910.29(f)(7) - Handrails and the top rails of stair rail systems are capable of withstanding, without failure, a force of at least 200 pounds (890 N) applied in any downward or outward direction within 2 inches (5 cm) of any point along the top edge of the rail.

Mounted Railing Case Studies

Durability of KeeKlamp

Braddock Bay State Park

Guardrail for a Water Treatment Facility

Railing FAQs

What is the difference between guardrails and handrails?

What are the OSHA requirements for a handrail?

How much weight should handrails support?

How many steps are required for a handrail?

How many steps are required for a handrail?

What is the maximum height of a handrail?

Ready to Get a Quote on Ground Mounted Railing?