How to Protect Workers While Unloading Flatbeds

Whether strapping down steel pipe or a 200-pound tarp on a flatbed trailer, you’ll most likely need to stand on the flatbed.

Since the standard flatbed deck is 60 inches tall, you are working at height, are exposed to a fall hazard, and need fall protection.

Loading and unloading flatbed trailers is a challenging task, often involving heavy and awkward loads. Choosing the right form of fall protection, like vehicle platforms, can be tricky. Especially when those loads can vary in shape and weight.

In this article, I’ll show you three different methods of fall protection and describe the risks and benefits of each. You’ll be able to decide which is best for you by the end of this article.

What Does OSHA Say About Flatbed Fall Protection?

No code in OSHA addresses flatbeds specifically. This means we will use General Industry standards to understand when fall protection is required and what that looks like.

General Industry standards govern all workplace situations not covered by an industry-specific standard like maritime or agriculture.

In General Industry, fall protection is required anytime a worker is exposed to a fall hazard 4 feet or more above a lower level.

Guardrails and overhead lifelines are accepted forms of fall protection. They are also the most common form of fall protection used with vehicles.

However, each one will have its own complications when working on a flatbed trailer. Let's look at each of these options as it relates to flatbed trailers.

Using Overhead Lifelines for Flatbed Fall Protection

Overhead lifelines can come in many forms. You can have a rigid overhead track that is freestanding or mounted to the structure of your building. You can also use a cable lifeline system attached to an appropriate structure above.

This type of fall protection will allow someone to have a free range of movement while walking on the flatbed if designed to do so. Overhead systems reduce the amount of space needed on the floor, making it easier for vehicles to participate in loading and unloading the flatbed.

However, there are restrictions you need to know when you choose to employ an overhead lifeline.

Any personal fall protection system, like a lifeline, needs to be designed, installed, and used under the supervision of a qualified person. This is typically an engineer with experience in fall protection, adding time and cost to your solution.

Any worker who uses a horizontal lifeline system needs to be authorized to use it, which requires training. They also need to have PPE that matches their body size and weight. Too light or too heavy could have unwanted complications for the user, resulting in harm.

More time. More money.

Another consideration is the limitation on users. Most overhead systems will limit you to two workers at a time.

One of the biggest hurdles to using this system on flatbed trailers is fall clearance. OSHA requires at least 2 feet of clearance below a worker and any lower level after the fall is arrested. With a 60-inch trailer bed, you don’t have a lot of leeway to make that happen after the self-retracting lifeline arrests the fall and the harness stretches.

For this reason alone, I would avoid using overhead lifelines with flatbed trailers if possible.

Using Guardrails as Flatbed Fall Protection

Besides eliminating the fall hazard, guardrails are the best form of fall protection.

OSHA-compliant guardrails should be 42 inches in height, give or take 3 inches. They should withstand 200 pounds of force in the outward and downward directions. And they should have a midrail halfway between the top rail and the walking/working surface.

Guardrails are safer than lifelines for a few reasons. They do not require any specialized training or active participation to use, like attaching to an anchor. There are no limits to the number of workers that are protected by a guardrail.

Some guardrails are specifically designed to sit in the rails of a flatbed, assuming that the flatbed you are using has them. These are easy to install and perform the function guardrails should.

When considering this guardrail style, know it requires rails to work properly. So, that may be a limitation for you. Also, it will reduce the amount of work surface for your employees to use when managing loads.

So, what do you do if you don’t have the rails or want/need the extra space?

Using Platforms for Flatbed Fall Protection

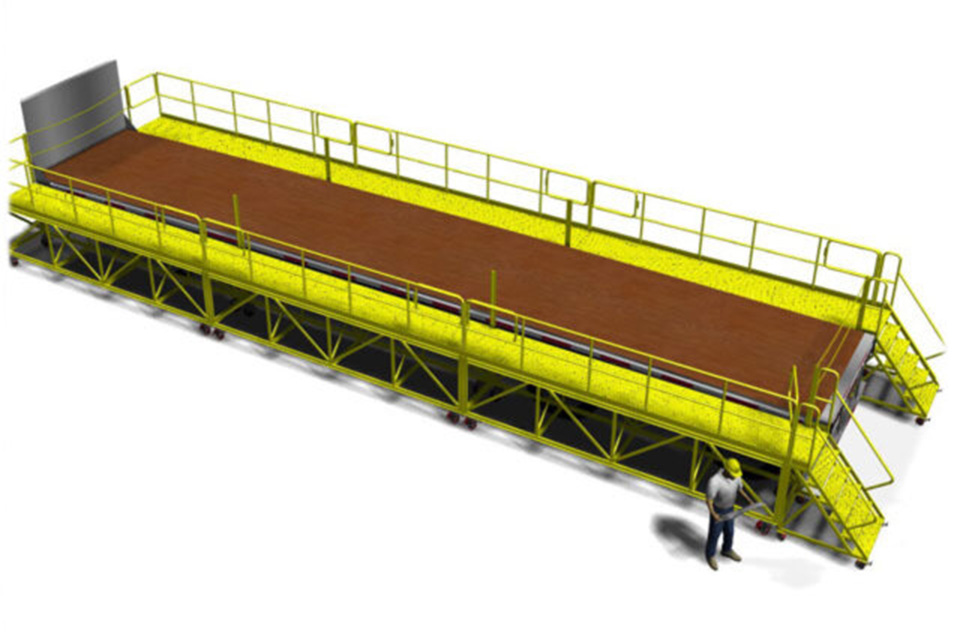

Vehicle platforms offer the collective protection of any guardrail system while adding additional surface space to work from.

Platforms come installed with a guardrail system, safety gates, and stairs. Using a stair system makes it easier for workers to access the platform. Carrying necessary tools or equipment, like a heavy tarp, is also safer.

You can design a platform to come in sections so that you can modify the platform to fit shorter flatbeds. Most vehicle platforms come equipped with casters to move from location to location.

On the note of casters, make sure that you use casters appropriate to your location. If you have rough terrain, then you are going to want a more heavy-duty caster. This will allow you to more easily navigate said terrain, as well as let the casters last longer.

Platforms do cost more than flatbed guardrail systems. Platforms also take up more space when storing than the flatbed guardrail system.

Choosing Your Flatbed Fall Protection

If possible, I advise using a platform system for your flatbed fall protection. The collective protection of the guardrail system and the additional workspace will offset the initial cost savings of other fall protection systems.

Managing uneven and heavy loads like sheetrock and steel pipe is difficult and dangerous. Having more surface area to work from will allow workers to better handle material. This protects the worker from injury, protecting the business from the emotional and financial cost of such an accident. It also helps protect the product from potential damage, reducing or losing its value.

If you’re ready to get started with flatbed fall protection or have additional questions, then contact one of our fall protection experts. We’ll help you navigate your specific job requirements to find the solution that works best for you.